Sustainable Construction Power: Harnessing Clean Energy Storage in the Construction of a Solar Project

A leading engineering and construction company used a sustainable, low-emission temporary power solution to support the construction of a solar project in Texas. Integrating a POWR2 POWRBANK battery energy storage system (BESS) with a diesel generator enhanced operational efficiency, reduced fuel consumption, lowered CO2 emissions, and decreased operational costs.

The Requirement

During construction of the solar array, a temporary power solution was required to power critical components. These components included a 12×60 office trailer, a shade trailer, and an ice freezer.

The Solution

- 40 kVA POWRBANK 40.60/240 Battery Energy Storage System

- 45 kVA Diesel Generator

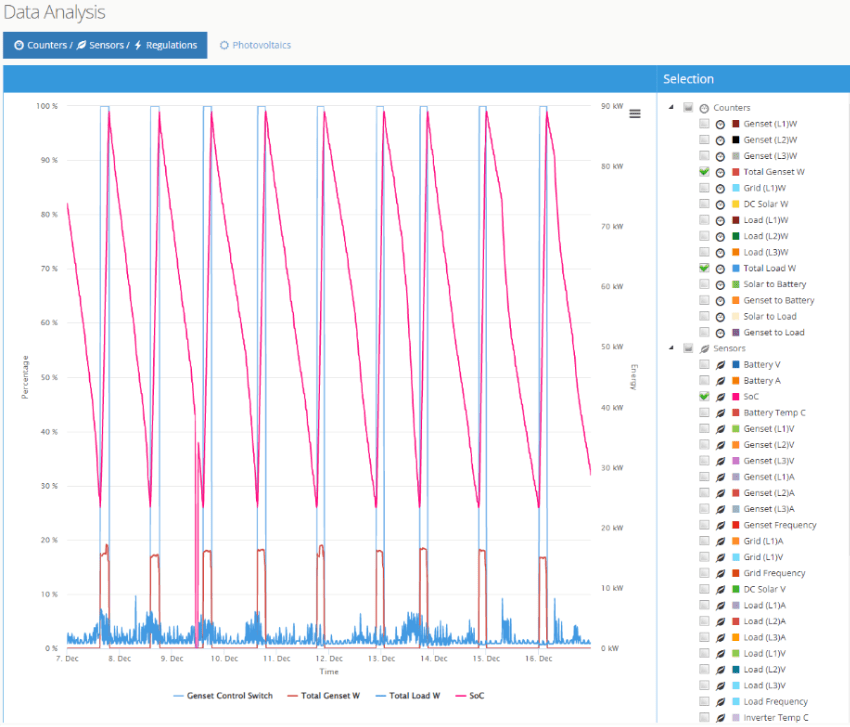

The POWR2 screenshot below displays the collaboration between the diesel generator and POWRBANK in powering the load. As illustrated, the generator turns on for roughly 6 hours per day which is just long enough to charge the battery. Once the battery is at 100% State-of-Charge, the generator shuts off and the POWRBANK powers the load for the remainder of the day. The cycle repeats seamlessly and can be monitored remotely.

| Standalone 45 kVA Generator | 45kVA Generator + POWRBANK | |

|---|---|---|

| Owning & Operating Cost | $2,868 per week | $1,397 per week |

| Generator Run Time | 168 hours per week | 44 hours per week |

| CO2 Emission | 7,373 lbs per week | 1,931 lbs per week |

The Results

In just over four months with the POWRBANK, the customer reported:

- 36.4% reduction in fuel consumption

- 51.3% cut in operating costs

- 73.8% decrease in generator runtime

- 109,617 lbs of CO emissions avoided

Reduced Fuel Consumption

Over a span of 141 days with the POWRBANK BESS, the customer reported a 44.4% reduction in fuel consumption. Without the POWR2 temporary power solution, the generator would run 24/7 and consume a total of 168 gallons of fuel per week. However, with the POWRBANK, the generator ran just 44 hours per week.

Lower Owning and Operating Cost

The Owning and Operating cost, previously standing at $2,868 per week, has been slashed to $1,397 per week with the integration of the POWRBANK. This includes reduced maintenance costs and labor hours spent addressing wet stacking issues on the Tier 4 Final rated generator. Maintenance labor hours saved were approximately 8.7 hours/week.

Generator Runtime Optimization

The hybrid power system not only resulted in reduced fuel consumption but has also optimized the generator runtime. In one week, the generator would need to run for a total of 168 hours if powering the load alone. With the assistance of the POWRBANK, generator runtime has drastically reduced to just 44 hours per week. This not only prolongs the life of the generator but also contributes to a more sustainable and environmentally conscious operational approach.

The substantial reduction in fuel consumption, optimized generator runtime, and significant cost savings underscore the benefits of adopting cutting-edge technology in large-scale construction projects.

POWR2 Portal: Total Load, Generator runtime, POWRBANK State-of-Charge.