Top Contractor Saves Significant Fuel, CO2 Emissions, and Generator Runtime at BWI Jobsite

POWR2 partnered with The Whiting-Turner Contracting Company, a top U.S. construction manager, to leverage POWR2’s POWRBANK energy storage system for a long-term project at Baltimore-Washington International Thurgood Marshall Airport to produce reliable, off-grid power. After one year, the POWRBANK, coupled with PV solar arrays, produced astonishing results, saving 11,357 gallons of fuel and 254,851 pounds of CO2 from being released into the atmosphere.

Selecting an Off-grid Power Solution

Whiting-Turner’s project is a multiple phased construction renovation for the Maryland Aviation Administration. The jobsite is located adjacent to the BWI Marshall airfield and requires a complete off-grid, stand-alone power set-up because grid power is not available. The standard option was to go with a diesel generator to power the site. However, Whiting-Turner sought a more sustainable, cost-effective solution. As a four-year customer of POWR2, they knew pairing the POWRBANK with a diesel generator and their own solar skids would significantly reduce generator runtime, thereby lowering emissions and saving fuel costs.

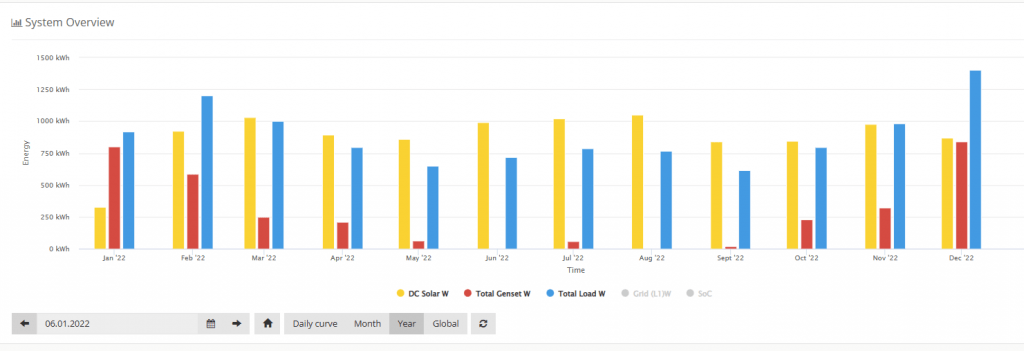

The POWR2 POWRBANK is an intelligent Energy Storage System that combines load-sensing technology with high-density lithium-ion batteries. As the primary power source, the POWRBANK supplies clean, silent energy to the load. The POWRBANK is complemented with two PV solar arrays to supplement the energy to the load, and charge the batteries when the solar output exceeds the load demand. When the batteries are depleted, the POWRBANK calls on the generator to recharge the system. Once the batteries are charged, the POWRBANK switches the generator off; the load is then supplied solely by clean power from POWRBANK. This cycle is seamless and smooth.

POWRBANK Powers Office Trailer Uninterrupted 24/7

At BWI Marshall, POWR2 added two solar chargers to the POWRBANK, enabling the addition of a unique solar skid system developed by Whiting-Turner to power their temporary office trailer with renewable energy. Off-grid jobsite trailers are typically powered by diesel generators, which need to be turned off when the team is not on site. Because of this, construction teams often risk plumbing freezing, cold mornings in the trailer, and no safety lighting at night.

Whiting-Turner’s solar skids and the POWRBANK power the lights, security systems, and HVAC systems for the triple-wide trailer 24/7. This set-up ensures that the systems are running uninterrupted without unwanted noise and CO2 emissions. The team does not need to shut down power when not on site.

In addition to the solar skids, Whiting-Turner utilized energy efficient strategies in the office trailer, to reduce energy consumption, which features a high-efficiency HVAC system, LED lighting, and composite insulation systems. The HVAC system reduces the load while still maintaining the desired heating and cooling temperatures. By combining this HVAC technology with Whiting-Turner’s solar skids and a POWRBANK, the team optimized fuel savings and further reduced generator engine runtime.

Results by the Numbers

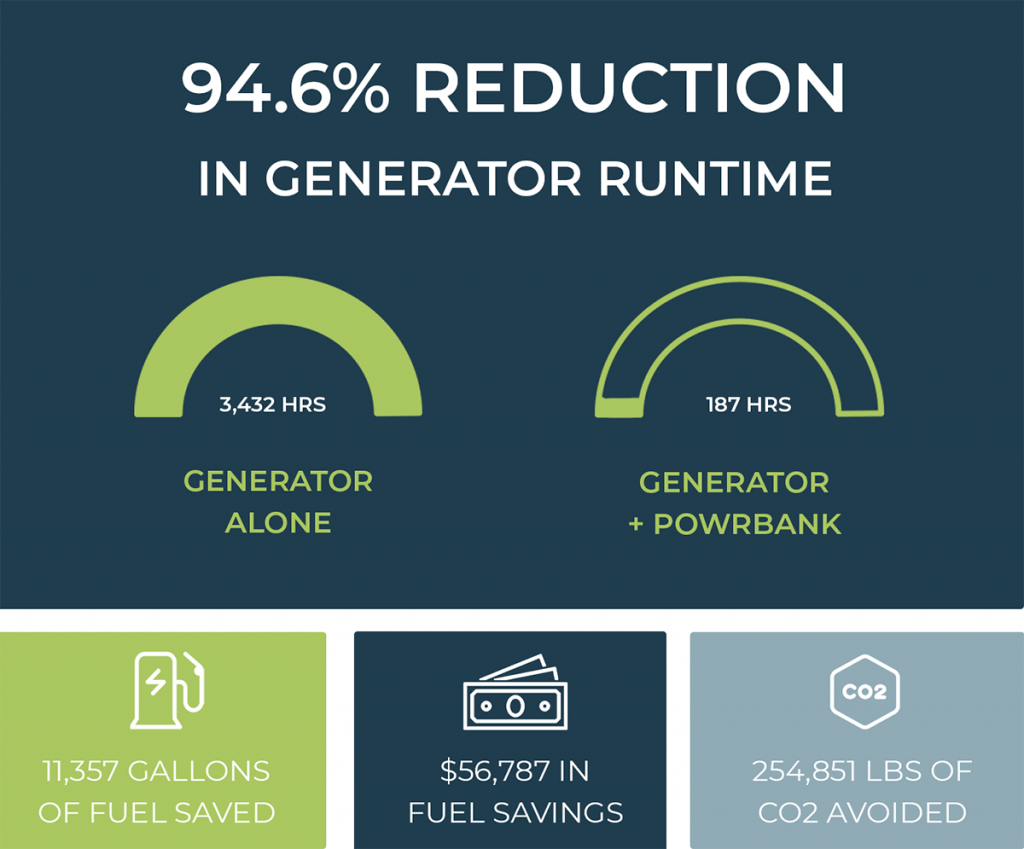

In one year, while the trailer ran 24/7, the generator only ran 187 hours (about 1 week 19 hours). When compared to a typical off-grid project trailer site utilizing only a generator, POWR2 and Whiting-Turner’s set-up, which included a generator, POWRBANK, and two solar skids, resulted in:

- 94.6% reduction in generator engine runtime

- 3,245 hours (about 4.5 months) of generator runtime saved

- 11,357 gallons of fuel saved

- 254,851 lbs of CO2 emissions avoided

- $56,787 in fuel cost savings

“The generator only ran 187 hours all year! That is amazing!”

These numbers consider 5.5 workdays per week x 52 weeks per year x 12 hours/day (6 a.m. to 6 p.m.) = 3,432 hours of required generator time. The savings is even greater considering that the POWRBANK allows power 24 hours a day.

Unexpected Outcome – POWRBANK Solves Low Load Issues

Whiting-Turner has experienced issues with generators over the years, including oversizing, wet stacking, refueling challenges, and low load periods in the Spring and Fall seasons. The immediate need for the BWI Marshall project site was a portable, temporary power solution, but over the course of one year, the benefits received were even greater.

By using solar energy and the POWRBANK, Whiting-Turner saved 3,245 hours of run-time on the generator. This resulted in minimal generator-associated costs, including refueling, repair, and maintenance costs.

The POWRBANK enables the generator to run at it optimal output (close to full-load), reducing the chances of wet stacking. Each time the POWRBANK required the generator to charge the batteries, the generator ran at full capacity, but only for short periods, eliminating no load or low load periods.

For more information on using POWRBANK battery energy storage solutions (BESS), contact POWR2.